Putting digitalization into practice in the glass processing industry has taken some time. But now the momentum has picked up and the number of users is accelerating rapidly. Why is this?

Pioneers like Glaston have helped fuel the demand for greater digitalization by educating customers about the benefits, demonstrating real progress along their digital strategy roadmap – and adding more customers and their data to the cloud to accelerate the entire movement.

We spent the majority of 2018 building our confidence by implementing ideas and collecting data to bring the benefits of digitalization that other industries are starting to enjoy to the glass processing industry. Now, we can look back and see our progress. We’re actually even further than we initially aimed. Our online reports have improved, and we’re really proud now to present them to customers and to the entire industry. Our work has led to a lot of information that now offers value.

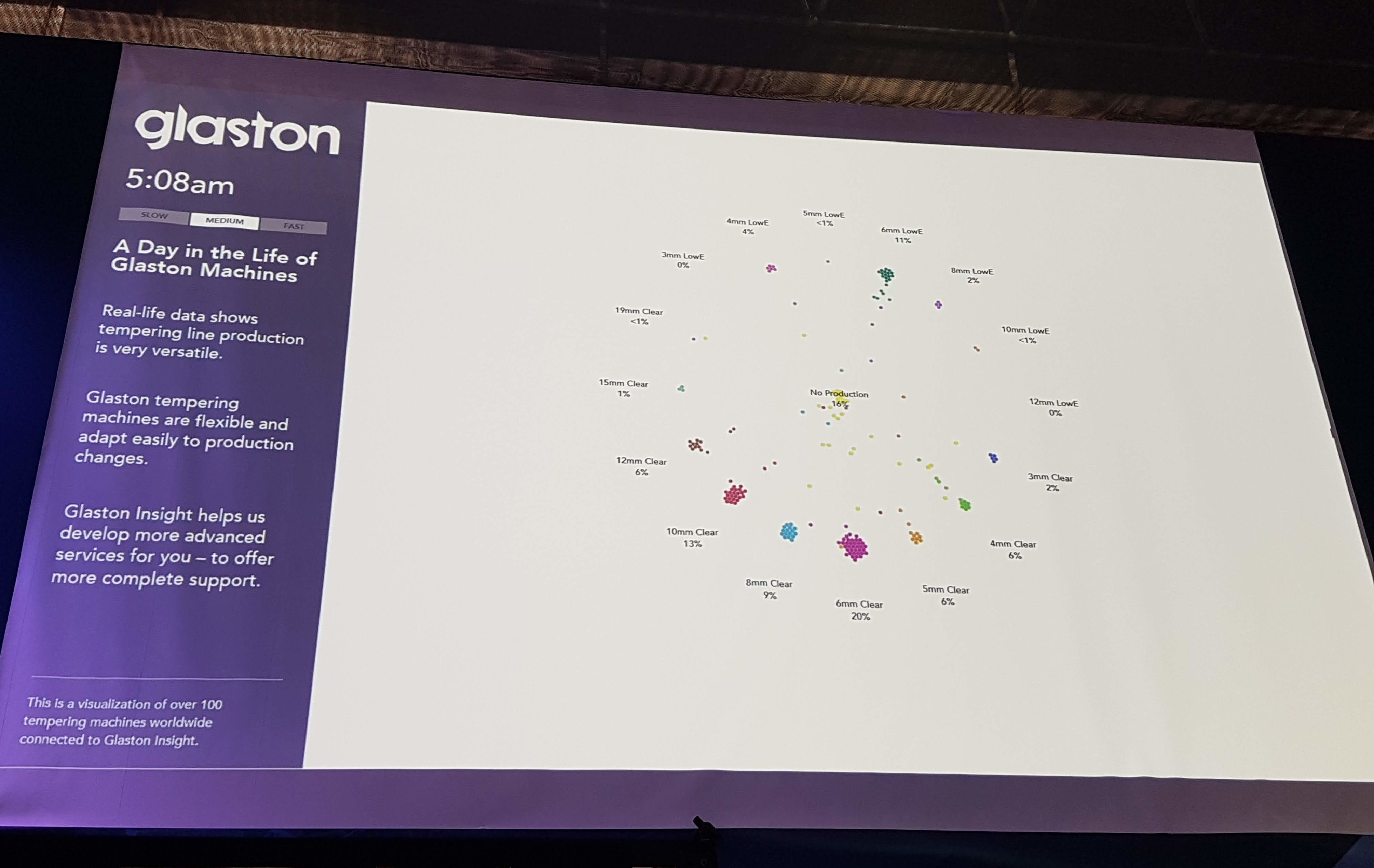

By the end of 2018 and according to plan, Glaston successfully reached several of its big milestones: over 100 tempering and laminating lines are now cloud-connected, and data from 1 million loads has now been recorded.

Growing numbers of glass processors are joining the digitalization movement because they understand the advantages. At the moment, 38 countries are represented with the largest number of processors being located in the US, Europe and then followed by Asia-Pacific.

But what do all these figures mean in practice?

These processors understand that by connecting their information, they can learn and improve their operating processes. They know they can fully trust the data so that everyone connected benefits. For them, the more they’re tapped into the cloud, the more they can learn about running their equipment smarter, finding ways to raise productivity and discovering ways to improve their quality. In short, making better business decisions that lead to greater profitability.

For machinery suppliers, like Glaston, the information gathered helps us offer new services based on data analytics.

We can see, for example, how our machinery is used, how various glass thicknesses are tempered and laminated – and learn more about the types of glass being run and their parameters. This helps us improve our own service offering to support our customers in reaching higher capacities and better quality.

Another development along our digitalization roadmap is to take artificial intelligence (AI) to the next level, which means enabling tempering and laminating machinery to become fully autonomous. Glaston is currently working intensively on adding machine learning and vision to its technology.

As part of this, we’ve implemented augmented reality (AR) and virtual reality (VR) to help our own people and our customers with training and maintenance tasks. Our new Support Room concept using AR was showcased for the first time at Glasstec last fall – and by the coming GPD Finland this summer, we’re pleased to be able to show everyone more!

There’s a lot of excitement around this entire movement right now since customers can see the real benefits of AI and also how other digitalization technologies can help them reach their own business goals. They can use these technologies for better production follow-up, to reach higher capacities and to learn ways to improve their glass quality with more intelligence.

For operators, too, digitalization will make their jobs much easier and less stressful. Still, even with fully autonomous machines, we will always need humans to take care of the machines, develop the processes and explore new types of glass for their markets. We won’t be operating without humans for many years to come, if ever. We need people to ask the questions – and partner with AI to create the world we’d like to envision.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.