Today, when energy efficiency is more important than ever, it’s a good time to speak about insulating glass spacers. In the same vein as the gas fill, glass spacers play a significant role in thermal performance of an insulating glass unit. Therefore, it is imperative to make sure your spacer technology is effective and sustainable.

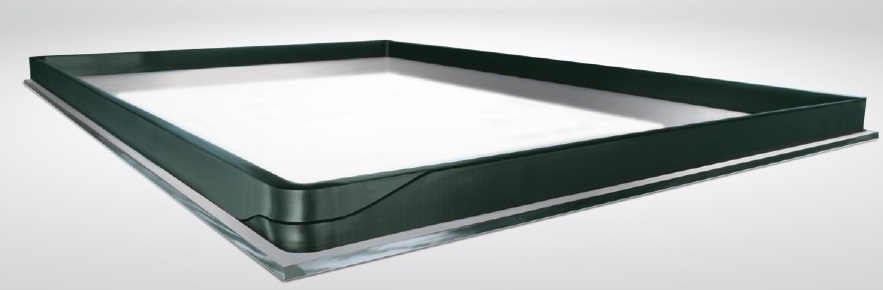

In an insulating glass unit, spacers determine the width of the gap between two or more sheets of glass. The primary role of spacers is to provide a fixed gap between the layers of glass.

Over the years, the glass industry has seen many developments and changes when it comes to materials and technologies used to make insulating glass spacers. Because spacers define the amount of heat and cold that can pass through the glass panes, spacer technology is one of the core factors ensuring glass performance.

Today, when demand for greener construction materials is high, ever more focus is placed on glass spacers capable of boosting the energy efficiency of insulating glass.

Insulating glass spacers are available in different materials, colors and a variety of thicknesses. For an insulating glass unit, all three are essential and affect performance. For example, even a slight change in the thickness of the spacer impacts its conductivity characteristics. Meanwhile, the material determines the amount of heat and cold that is able to pass through the glass and, therefore, plays a big role in the unit’s energy efficiency.

When it comes to material, spacers are typically divided into two main groups – aluminum or warm edge spacers.

Originally, aluminum spacers were the most widely used type of spacers. This material has been available for decades and provides the basic performance level.

While being a structurally strong material, aluminum is a very efficient thermal conductor. This means aluminum spacers make it easy for indoor heat to escape outside. What’s more, the cold glass edges caused by the aluminum create a temperature difference between the center of the glass and its edges. Consequently, the insulating glass units are prone to condensation.

Growing energy requirements, though, created demand for newer solutions. So, warm edge spacers made from low-conductivity materials were introduced as a higher-performance alternative to traditional aluminum spacers.

Warm edge technology has changed the window market radically. Not only does it help prevent heat loss through windows and improve the unit’s energy efficiency, it also reduces the condensation issue.

Today, there is a broad variety of warm-edge spacer designs available. Each eliminates the effect of heat loss to a certain degree while offering different levels of structural integrity.

Stainless steel materials, along with their properties, are similar to those of aluminum spacers. However, stainless steel has only one-tenth the thermal conductivity of aluminum and improves condensation resistance.

Still, stainless steel spacers are many times more conductive than other warm edge spacer options.

This type of warm edge spacers is typically made of plastic materials, such as polycarbonates, polypropylene and others, combined with low metal shims.

Flexible spacers have been developed using pliable, flexible thermoplastic or silicone-based materials with incorporated molecular sieves.

Among these, the hot melt butyl type of spacers without any additives stand out most. And TPS® is a perfect example.

Since being originally launched in 1994, TPS® technology has reshaped the insulating glass spacers market considerably. For insulating glass manufacturers, TPS® provides excellent thermal insulation with many other significant advantages.

Advantages of the TPS® technology

Active and effective vapor barrier

The modern insulating glass spacers market is indeed very complex and diverse, making it impossible to cover all aspects in a short blog. But if you are still looking for more, our IG Manufacturing Line Buyer’s Guide is here for you.

This eBook also contains a comprehensive comparison chart of spacer bars arranged by manufacturer.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

No comments so far.