A tempering line investment is usually one of the biggest investments a glass processing factory can make. However, the costs related to the investment are more than just the machine alone. The calculation may seem simple, however, different companies value different factors in a very different way.

The methods of calculation might vary, but one thing remains: once the full scope of calculations is done and over with, you’ll see that the reliability and quality of the end product are far more important than just the price at the purchasing moment. Anybody can check this by just eliminating a certain amount of sold products. This will have a drastic effect on the payback, since fixed costs are running, but no revenue is coming in.

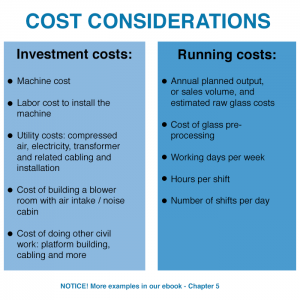

It is important to understand that the tempering line investment includes different utilities that are needed to operate the line. In order to get the whole picture, we have collected a list of the cost components that you should consider in your calculations.

If you want more in-depth cost structure instructions, please, download our eBook on the topic! Please note! It doesn’t cost you anything.

The cost structure of a tempering process gives you a framework. However, the main decision factor is the business case as a whole. The reasons for investing in a tempering line may vary a lot. Still, here are some questions you should ask yourself anyway when considering such investment.

Investment project related questions:

Utility related questions:

Machine/supplier comparison related questions:

The answers to these questions will be different for everyone. And the list is not even complete. Even though quantifying the answers will be somewhat difficult, we hope that you give it a try regardless. The value you provide to your customers is the key to your future success – and returns.

After completing your analysis, you will be able to make your best guesstimate on the forecasted profits. By comparing future profits with the cost structure, you will get the machine’s payback time. After you have done your calculation, you can most likely confirm Benjamin Franklin’s famous saying:

“The bitterness of poor quality remains long after the sweetness of a low price is forgotten.”

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.