During recent weeks, we have all seen and heard about the Volkswagen emissions scandal. If you have missed the news, here’s a short recap of the situation: Since 2009, Volkswagen had been installing a computer program that decreased a car’s emissions when being measured. As you might have guessed, the whole world is shocked and angry.

Note to self: Cheating is not a sustainable business model.

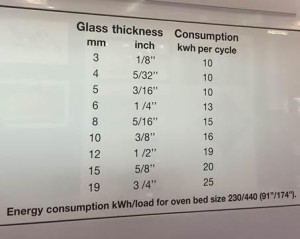

I spent this week at the Vitrum exhibition in Milan, where glass industry suppliers were presenting their latest innovations and offerings. When walking around the exhibition, I noticed one Italian tempering line manufacturer with the following picture on their stand wall:

What? Are operators in the glass tempering business falling into the Volkswagen trap as well?

To prove my point, I need to go through the physics behind glass heating. Let’s take an example of 5 mm glass with a loading area of 2.3 m x 4.4 m, as in the given picture. The table above states that the energy consumption per load is 10 kWh.

According to the laws of physics, glass requires a certain amount of energy before it reaches the tempering temperature. This temperature does not depend on the tempering line; it’s just a physical fact.

The exact number is 0.476 kWh / (m² * mm). To be more specific, each square millimeter requires 0.476 kWh before it reaches the tempering temperature.

Note! If you are interested in the full formula, please download the “Tempering line buyer’s guide” and you will find it on pages 37–38.

Based on the same principle, 5 mm glass will require a theoretical minimum of 5 mm * 0.476 kWh / (m² * mm) = 2.38 kWh/m² for it to reach the prime heat condition.

Let’s take the example where the area of one load would be 2.3 m * 4.4 m = 10.12 m² as in the picture above.

In this case, the theoretical minimum of energy needed to heat the load is 2.38 kWh/m² * 10,12 m² = 24 kWh. Notice that 24 kWh is required only for heating. This does not include the energy needed to create the tempering pressure, also known as quenching.

In essence, the 10 kWh stated is enough to heat less than half of the load. But even in this case, it does not include the energy needed for tempering. In my humble opinion, the above picture is just wrong, and the information given is false advertising.

The sad part is that customers truly depend on the data the suppliers provide. It’s a huge responsibility because there is no way that “normal” customers have any chance of realizing that they are being misled.

Here are couple of pointers for anyone who is about to invest in a tempering line and wants to be sure that the energy consumption figures provided match the reality:

1. Always demand that the energy consumption figures are included in the contract, with penalties for exceeding the defined values.

2. Define the basis for the energy consumption figures: glass type, loading area, production speed or quality. Make sure to be extra clear on these points.

3. Double check the values with the basic physics calculation above and aim to understand the different factors that impact the tempering line’s energy consumption.

If you’re interested in learning more about this topic, I suggest downloading the “Tempering line buyer’s guide”. This eBook includes detailed information about the tempering line’s energy consumption. The guide also includes other valuable information to consider when investing in a tempering line.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.